Innovative production technologies...

Innovative production technologies...

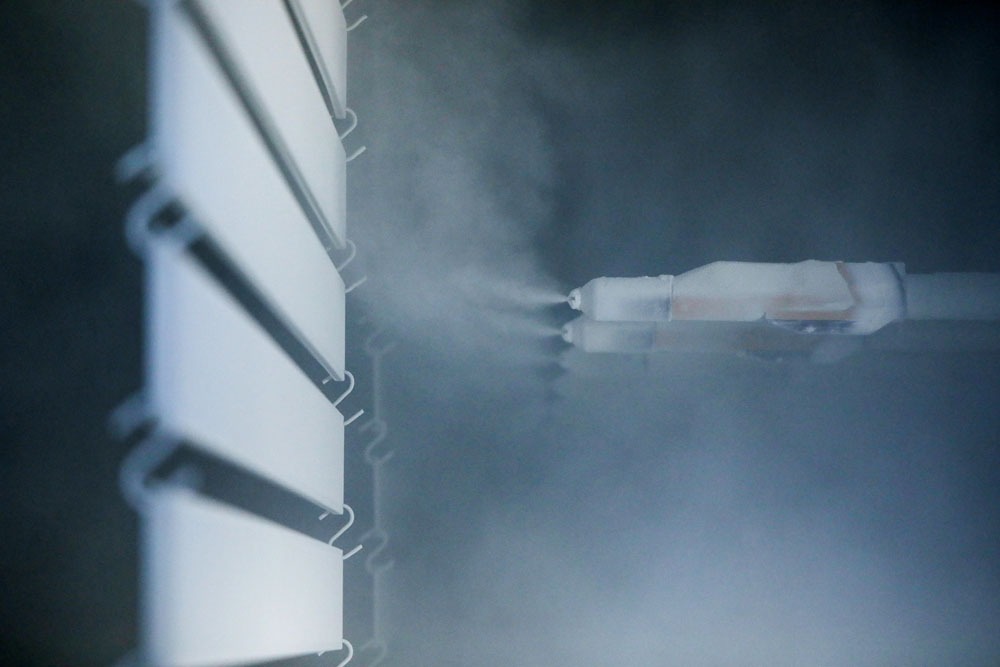

In the electrostatic powder coating facility, in line with our painting expertise, a total of 10-stage spray alkaline degreasing, demineralization process and trication zinc phosphate coating with chrome-free passivation are applied as pre-painting surface treatment. In three separate paint booth units, each equipped with 12 guns and robotic control, different colors can be applied. The conveyor system has a total length of 400 meters, where parts up to the dimensions of 1500 mm x 3000 mm can be painted. After painting, our test laboratory conducts tests such as corrosion resistance, gloss, impact deformation, hardness, and conical bending.