Innovative production technologies...

Innovative production technologies...

Your Solution Partner

With our experience in the production of white goods parts and our fully equipped machinery park, we provide high-quality parts to the white goods sector.

More

While offering high-quality OEM services to customers in the white goods sector, we also market our in-house white goods products under our TRAGEN brand.

More

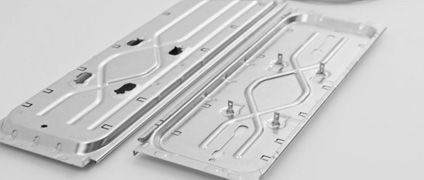

We provide high-quality ODM (Original Design Manufacturing) services requiring skilled craftsmanship in the production of automotive parts to ensure the efficiency and safety of vehicles.

More

With our high-tonnage presses and fully equipped sheet metal processing machines, we manufacture various metal parts that can be customized according to customer requirements.

MoreWe in Numbers

32,000 m2 open +

24,000 m2 indoor space

500,000 cookers +

320,000 ovens + 270,000 hoods

36,000 Tons of sheet

metal processing capacity